Warranty:1 year,

Place of Origin:Hebei, China

name:3d wire mesh wall panel machine for houses

Application:Building

Raw material:EPS block and wire mesh

Type:Automatic

Usage:Producing Wall Panel

Color:Customized

Packaging Details:3d wire mesh wall panel machine for houses For big parts, wrap the machine with pe sheets. For small parts, we pack them in wooden box or cartons.

1. What is EPS 3D panel?

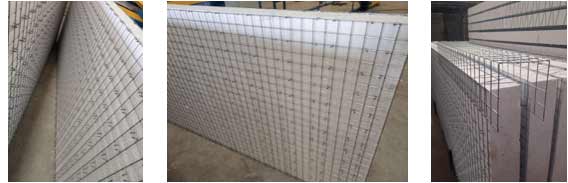

3D panel is a prefabricated Three Dimensional Lightweight Structural panel consisting of a super-insulated polystyrene core sandwiched between two engineered layers of 10 ga Steel welded wire fabric mesh. To complete the panel form process a 10 ga Steel wire truss is pierced completely through the polystyrene core and welded to each of the outer layer sheets of 10 ga Steel welded wire fabric mesh. Once a special shotcrete concrete is applied to each side of the panel, the strong Three Dee insulated concrete structure is completed. The 3D Panel is a unique and effective way to easily create a strong insulated concrete building or wall.

2. EPS 3D panel structure

Components of the 3Dpanel include :

(1)Foam core for insulation.

(2)Wire mesh on inside and outside.

(3)Welded truss of wire cross pieces.

(4)Sprayed concrete on both sides ("shotcrete").

3. EPS 3D panel raw material

1) Low carbon steel wire (Normally 2.0mm -3.0mm)

2) EPS(Expanded polystyrene) core (Normally 50-100mm)

High automatic degree:

The machine is controlled by computer. It has three ways of working: inching, single-step, automation. High degree of automation can shorten the working time and improve the work efficiency. It is also convenient for maintaining.

Property of electron component is stable.

It adopts good-quality pneumatic components and Mitsubishi Siemens PLC (according to the customer’s requirement) and has good performance. It is easy to operate and repair.

High output.

Its yearly output can reach 200,000 square meters.

Good quality.

The gap between the wire mesh and EPS block is uniformity and regular. And it has accurate size and good plainness.

Intense-welding:

Pulling-out force of the welding pot is stronger than 400N.

4. Normal EPS 3D panel specifications:

Truss Wire:2.0mm -2.8mm galvanzied.

Mesh Wire:2-2.8mm Mesh hole:50 *52mm

Panel Length:3000mm or 6000mm

Panel width :1220mm EPS Insulation Core:50-100mm

5. EPS 3D panel Properties

1). Thermal Insulation: The EPS squeezing foaming polystyrene that is famous for the internal thermal insulation is used and reduces the loss of heat. It also makes the comfortable indoor space regardless of temperature variation in the winter season.

2). Fireproofing: It has passed the 120 minutes fireproofing test of national construction institute and has also been approved as the fireproofing materials for internal & external construction stuffs.

3). Moisture proofing: As we have used the high performance foaming polystyrene, it shows an excellent prevention against the condensation on the wall. (As for the usage of external wall, the exterior on the external wall needs the waterproofing mortar)

4). Soundproofing :On the base of sound insulation performance test, it has shown a distinguished feature of soundproofing among others. Especially, it shows a heightened operation capability with both sides plasterboard.

5). Lightweight: It only weighs a quarter of the masonry wall, which alleviates the fixed load of structure and also highly recommended in the enlargement of old buildings.

6). Structure: It is used for every construction like residence and apartment and is highly recommended .

7). Variety: It can be designed in a varied form without any professional knowledge, and fits for the round-typed materials as increasing 10% indoor space compared with masonry structure.

8). Economical Efficiency: As it is a standardized factory product, easy to construct, and allows us to execute the masonry, insulation, plastering at the same time, it surely reduces the construction time down to a third.

9). Shortening of Construction Time: As we said above, it is easy to execute and able to curtail the construction expense with the high efficiency in thermal insulation. It also boils down the framing expense as a lightweight material, which is definitely economically effective.

10).Withstand earthquakes, hurricanes and typhoons: The monolithic structure with 3D panel enables it to withstand earthquakes, hurricanes and typhoons. Many 3D buildings have endured hurricanes with no water penetration or damage, earthquakes with no cracking, and at the same time provided a comfortable and energy-efficient environment for the residents.

ABOUT "EPS 3d panel machine/EPS WIRE MESH 3D WALL PANEL MAKING MACHINE" you may like:

REVIEWS: