Condition:New

Warranty:1 year

After-sales Service Provided:Field installation, commissioning and training, Engineers available to service machinery overseas

Place of Origin:China

Brand Name:RUNJIE

Voltage:380V

Application:recycle eps waste

Automatic Grade:Semi-Automatic

Dimension(L*W*H):10000x3300x2500mm

Applicable Industries:Manufacturing Plant

Key Selling Points:Easy to Operate

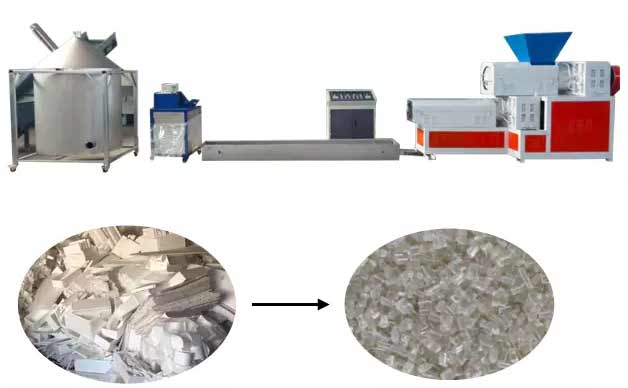

Product name:eps thermocol recycling machine and pelletizing machine

Raw materials:eps waste

capacity:200-300kg/hour

manufacturing type:extruding

Function:to make eps waste into granules

Final product:gpps granules

Working principle:heating and extruding

Screw:two screws

Production Capacity:200kg/h

Power(W):85kW

Weight:4000kg

Processing Steps of eps recycling machine and pelletizing machine:

Collect eps waste. Pick out the waste from the eps products.

Crush the waste eps products with crusher and store the crushed eps into a storage room.

Blow the crushed eps from the storage room into the eps silo above the machine. The eps was melted in the first extruder. Then the melted eps is transported to the 2nd extruder for plasticizing.

The filter net on the die head will filter the dirty things. When the filter is too dirty, use the hydraulic net exchanger to change a clean net.

The ps material passing the filter is like noodles. They are of high temperature after leaving the extruder. So they have to be put into the water tank for cooling.

The cooled ps noodles will be cut into pellets by cutting machine and then be transported into the granule silo.

EPS Styrofoam Recycling Machine Details:

I. Crusher

The crusher is horizontal type. The inlet is just on the ground so that the eps waste can be put into the crusher easily.

II. Storage Room (Customer Prepare Locally)

After crushing, the crushed eps should be stored in a big storage room. The storage room is made by the buyers according to their workshop conditions.

III. Extruders (Melting & Plasticizing Section)

The crushed eps is blown into the extruders for melting and plasticizing.

The machine has two extruders.

IV. Hydraulic Die Head & Net Exchanger

The melted & plasticized material is a kind of ropy fluid material. It passes the die head filter mesh which is installed on the die head so that the dirty things inside can be filtered out. After filtering, the material will be extruded through the cores.

When the filter mesh is dirty, we will change the mesh by hydraulic net exchanger. The filter can be 20-80 mesh according to customers’ choice. The more mesh, the cleaner the product.

V. Water Tank

After the melted noodles are extruded, they have to be cooled by the water in the water tank so that it can be cut into granules.

VI. Granule Cutting Machine & Granule Silo

After the materials come through the water, it will become crispy and then be cut by the cutting machine into granules. The cutting machine is installed with hobbings and there is no noise during cutting process. The hobbing also has long life. They can cut 700 tons of granules before getting worn out.

VII. Electric Control Cabinet

We are a prestigious plastic recycling machine manufacturer in China.

We has more than forty years of professional experience in plastic recycling machine.

We supply plastic recycling machines,eps machine, eps block moulding machine,eps shape moulding machine,eps compactor,eps 3d panel machine and many more.High capacity and less energy consumption are the features shared by all of our products.

All of our machines are customized depending on customers’objectives.

| EPS Recycling Machine Specification | ||

| Crusher | Dimension | 1500x1000x1000mm |

| Inlet Size | 1000mmx680mm | |

| Weight | 600kg | |

| Motor Power | 11kW | |

| Blower Motor | 2.2kW | |

| First Extruder | Extruder Diameter | 325mm |

| Screw Material | 45# steel, high-frequency quenching | |

| Screw Length | 1050mm | |

| Gearbox | hard-teeth gear | |

| Motor | 37kW | |

| Heating Ring | Cast Aluminum | |

| Second Extruder | Extruder Diameter | 125mm |

| Screw Material | 45# steel,high-frequency quenching | |

| Screw Length | 1400mm | |

| Motor | 15kW | |

| Heating Ring | Cast Aluminum | |

| Cooling Water Tank | Hydraulic Die Head | 250x250mm |

| Hydraulic Station Power | 2.2kW | |

| Die Head Core Number | 22 | |

| Water Tank Dimension | 3000x500x250mm | |

| Water Tank Material | Stainless Steel | |

| Granule Cutting & Granule Silo | Cutting Machine Dimension | 800x550x1100mm |

| Cutting Machine Weight | 150kg | |

| Hobbing Quantity | 19 pieces | |

| Granule Silo Dimension | 1100x1100x2500mm | |

| Silo Material | Stainless Steel | |

| Electric Control Cabinet | Contactor | CHINT |

| Temperature Controller | CHINT | |

| Air Switch | CHINT | |

ABOUT "EPS RECYCLING MACHINE" you may like:

REVIEWS: