What things should we pay attention to when we use the eps block molding machine?

1. To operate eps block molding machine, the operator must be familiar with the basic knowledge of the machine and the production process and working principle, and must be trained before operating on the machine.

2. EPS raw materials: The eps particles should be larger than φ1mm, raw materials with 16 mesh or more. If you use small particles or a mixture of large and small powdered materials, it is easy to block the mold vent and affect the quality and production efficiency of products.

What should we do before we start using the eps machine?

1.Before installing the machine, first check the package, then check whether the appearance of the machine is good, and check the accessories according to the packing list. If damage or missing accessories are found, please report to us immediately.

What are the requirements for using EPS pre-expander?

1. The steam must be saturated steam, working pressure is 0.5 ~ 0.8 Mpa; dynamic pressure is 0.2 ~ 0.3Mpa. It is critical that the steam is saturated steam, because if the steam pipe is too long or too small, or the pressure of the boiler is not enough, then it is easy to form water vapor. If unsaturated steam enters the barrel of the pre-expander, it will make the surface of the EPS raw material contains too much water so that the raw material expansion ratio is difficult to achieve the same. So the steam inlet pipe diameter must be 3-2.5 inches and the pipes must be insulated well. The distance between the eps machine and the steam accumulator is normally 5-10 meters.

Precautions For Using EPS Pre-expander

1. In the event of a sudden power failure, EPS Pre-expander will automatically close the steam valve, open the material door and the compressed air valve to cool it to prevent the foam material in the barrel from condensing into agglomerates. If you want to discharge the raw materials in the barrel, you can blow out the foaming materials in the barrel with a blower or compressed air, and then separate them according to the actual situation of the foaming material.

How to Use waste EPS?

EPS products are widely used for packing because of its unique advantages of insulation and protection. The bad effect following with this phenomenon is that we can find a lot of waste eps everywhere. Many people know that eps can be recycled and used again, but they don’t know where and how to use them. Today, let me explain to you in detail.

Multiple Usages of EPS (Where can EPS be used? )

EPS is widely used in our life. Now let me explain to you in detail:

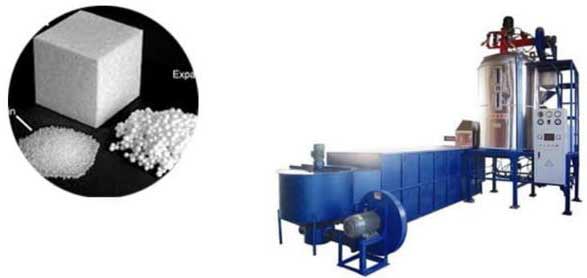

1.After the eps raw materials are expanded, we can get eps beads. These beads can be used as the following:

How to choose the right eps pre-expander machine?

EPS products are widely used in different fields. They can be used to make eps blocks for wall and roof insulation, they can be used for packing fragile products as a cushion, or for packing fish or vegetables to keep them fresh, to make formwork for building houses, or to use only the beads for making lying bags, to mix with cement to get lightweight concrete, or to make lost foam products for making auto parts, etc.

Main Types and Characteristics of Foam Shape Molding Machine

EPS products are widely used. Packaging boxes of seafood, vegetables and fruits in daily life, shock-proof packaging of air conditioners, televisions and other household appliances in industry field, lost foam in the foundry industry, building modules used in construction, etc.

Advantages of Houses Made Of ICF

ICF (insulated concrete formwork) is a way of building houses which is greatly promoted by many building experts in the world. ICF blocks are made of EPS with hollow cores inside. When we build houses, we put steel rebars inside, then fill the hollow cores with concrete. After it cures, the concrete can work as the load-bearing part and eps can work as the insulation layer. It has the advantages of easy operation, fast construction speed, heat preservation and insulation, earthquake proof, etc.

WHY CHOOSE OUR EPS FOAM MACHINE?

MAKING EPS PRODUCTION LINE ESTALISHED IN 1988.WE MAKE NOT ONLY MACHINES BUT ALSO EPS PRODUCTS.

The production then we improve our machines according to that. For example, for our eps concrete wall panel line, we specially designed the mixer, it is enough for 20 moulds so that our customers don’t need to change the line when they increase the capacity in the future. We also designed the mould which we can drive it like driving a car. It is much safer and easier than a pulling machine like what other companies are using.

EMAIL:info@eps-cn.com

TEL&WHATSAPP:+8619963847768