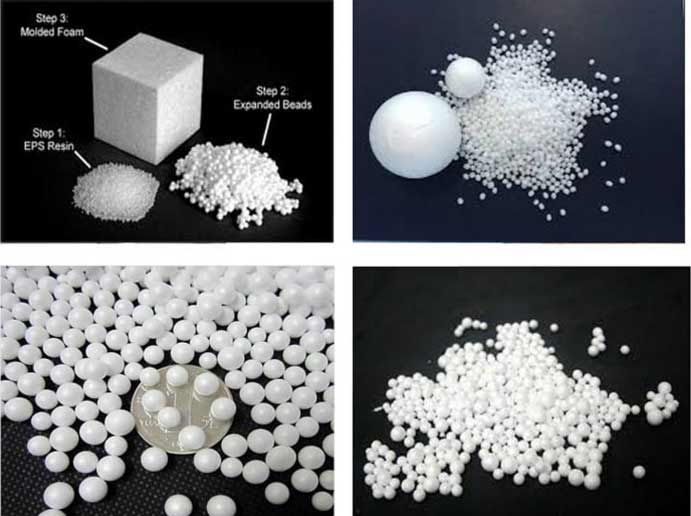

EPS products are widely used in different fields. They can be used to make eps blocks for wall and roof insulation, they can be used for packing fragile products as a cushion, or for packing fish or vegetables to keep them fresh, to make formwork for building houses, or to use only the beads for making lying bags, to mix with cement to get lightweight concrete, or to make lost foam products for making auto parts, etc.

For different purposes, we need to use different kinds of eps raw materials and expand different densities of eps beads. This requires us to choose the right eps pre-expander machine for different jobs.

Some beginners sometimes are confused, when they searched online and asked about price, they will be surprised to see that some quote very cheap price for the pre-expander while others quote a very high price. To know the reason, first, check the name of the machine, is it “continuous eps pre-expander machine”? Or “ full-automatic batch eps pre-expander machine”? And what’s the difference between them?

Continuous eps pre-expander machine is almost obsolete now. First, the capacity is small. Normally the model of such expanders are model 90, model 110 or model 120, while automatic batch pre-expander is model 140, 150, 160, 180 or 200. Secondly, continuous pre-expander consumes more steam and it can’t make low-density beads. Automatic batch pre-expander can save almost half of the steam for making the same capacity beads and it can get low density as about 4kg/m3. So, don’t be confused by low price only.

If you want to make eps products for lost foam casting, then the normal pre-expander doesn’t suit you. You need to choose the lost foam special-purpose pre-expander. The eps beads for lost foam casting usage is normally very small, the finished product density is also very high, some even reach 50kg/m3 or even higher. They also require the beads are even. The special pre-expander for lost foam can make very precise foaming when it expand high density beads which the normal pre-expander can’t make it.

PREVIOUS: Main Types and Characteristics of Foam Shape Molding Machine

You may like: